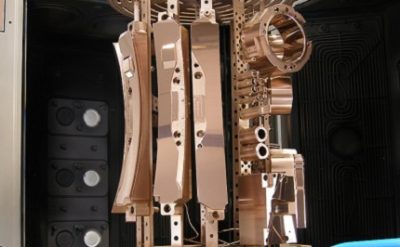

BÖHLER Mexico is home to a state-of-the-art Physical Vapor Deposition (PVD) coatings center, equipped with the latest in PVD coating process technology. PVD is a vacuum coating technique, which creates a film on the surface of the required material to maintain its hardness and improve the substrate properties in order to reduce many wear issues. The film improves part quality, creates higher productivity, and increases tool life. A major benefit of PVD coating is its use of low temperature during the procedure, which avoids distortions in the tool.

BÖHLER’S PVD coatings center specializes in creating custom coatings for the automotive, die casting, aerospace and plastic injection tooling industries, but is committed to accommodate a wide range of customer needs.

The coating center works side by side with the BÖHLER steel division and thermal processing division to offer our customers a complete solution – we are able to advise on an application with material selection, heat treatment specifications and coating technology.

At BÖHLER, we are devoted to providing on-time delivery, competitive prices for high performance coatings and exceptional customer service.

For more information about our complete line of products and services, please contact one of our application specialists.